PINION AND FIT:

TECHNOLOGY OF THE AUTOMOTIVE INDUSTRY NOW ON E-BIKES

From model year 2024, the FIT e-bike system will be available together with the Pinion «Motor.Gearbox.Unit». But that’s not the only innovation: With the approach of combining the gears and the motor in a single drive, the new Pinion «Motor.Gearbox.Unit» also revolutionizes the drive market – bringing technology from the automotive industry to the e-bike.

AUTOMOTIVE TECHNOLOGY ON E-BIKES

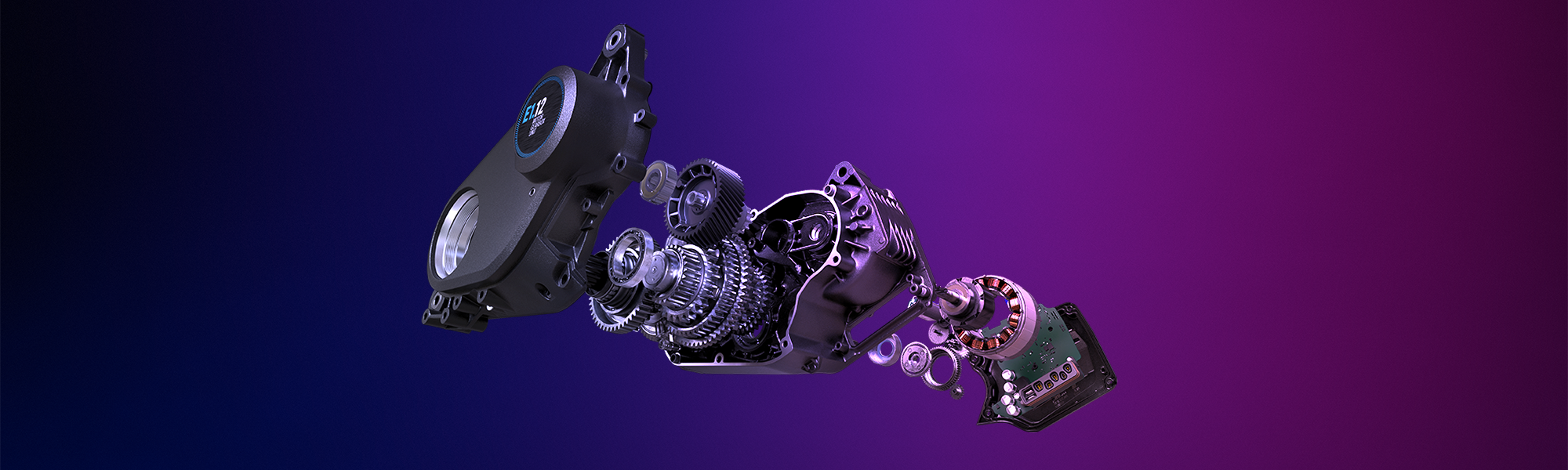

Two become one. This is the easiest way to summarize the approach of the new Pinion MGU. While most e-bike drives on the market feature the motor and gears as separate components, Pinion has now developed a drive that contains everything in one package. Specifically, the Pinion «Motor.Gearbox.Unit» (or Pinion MGU for short) unites an electric motor, Pinion transmission technology and electric gears to create its own drive system. The result is not just another mid-drive motor for e-bikes, but an entire powertrain in one unit.

The new Pinion MGU is a further step in a development that has been on the horizon for several years: Technology from the automotive industry is increasingly being used on electric bicycles. There are now plenty of examples of this, for example in the form of anti-lock braking systems (ABS), tire pressure sensors and lighting systems with main beams. In the case of the new Pinion MGU, it is the special construction: Based on proven automotive transmission technology, the Pinion gearbox uses what is known as spur gearing with two gear sets connected in succession. The individual transmission ratios are then determined by matching the two sub-gearboxes with different gear pairings.

GEAR SHIFTING INSTEAD OF DERAILLEUR GEARS

It is not surprising that automotive technology is also increasingly being used on e-bikes. Especially in cities, e-bikes have long since established themselves as a mobility alternative to cars. And with its increasing electrification, the originally purely mechanical bicycle is benefiting from the expertise of automotive engineers.

The example of the Pinion MGU clearly shows why automotive technology can often make sense on e-bikes: While classic derailleur gears are absolutely useful on organic bicycles, they quickly reach their limits on e-bikes when subjected to higher loads. The additional forces are a strain on the gears and cause wear to escalate enormously. This is why they have never been able to establish themselves on cars or motorcycles. Instead, the focus was on gear shifting at a very early stage. The situation is very similar for e-bikes, which are equipped with increasingly powerful electric motors. It was therefore only a matter of time before the corresponding gearboxes were used here.

WHAT ADVANTAGES ARE THERE OF COMBINING THE MOTOR AND GEARS ON AN E-BIKE?

The motor and gearbox in one unit – this approach is still relatively new on e-bikes. However, the advantages are obvious:

- The motor and gears are neatly integrated into the e-bike. So there are no exposed shifting components.

- This improves shifting performance.

- But wear and maintenance are also minimized, as this kind of system is cleaner and less prone to errors.

- Last but not least, e-bike designers also have more freedom, as they have to pay less attention to the additional shifting components.

BETTER TRACTION AND BETTER SHIFTING EXPERIENCE

Gear shifting instead of derailleur gears – the different advantages illustrate very well why the Pinion «Motor.Gearbox.Unit» can be seen as a sort of preview of the future of the e-bike. This is also evident when you take a closer look at e-bike construction because the omission of the external derailleur and the cassette on the rear wheel significantly reduces the unsprung mass, resulting in better frameset performance and ultimately more traction – one of the most important characteristics of every e-bike and on every surface.

And riding itself is also simplified. Thanks to the connectivity between the individual components, ensured by the FIT e-bike system, the motor speed can be adjusted precisely to the engaged gear and pedaling frequency. This means that the speed and assistance of the motor are precisely matched to the respective situation. With the appropriate settings, automatic gear changes are also possible – similar to automatic transmission in a car.

THE FUTURE OF E-BIKE TECHNOLOGY

Whether tire pressure sensors or the combination of drive and gears – in summary, it can be said that the introduction of automotive technology on e-bikes is likely to give the electric bicycle further tailwind. The Pinion «Motor.Gearbox.Unit» is a further milestone in this technological development direction, which ensures that the boundaries between automotive and bicycle technology continue to merge. Or to put it simply: Two become one.

More information about the Pinion «Motor.Gearbox.Unit» can be found on the following site:

20.06.2023